Adding Styrene Spacers

When I build turnouts I make them “DCC friendly” by isolating the frog. This is done by cutting a gap in the rail with a fine jeweler’s saw. You could be fine just leaving it but to be safe I recommend adding styrene into the gap. The nickel silver rail could expand slightly and it only takes the tiniest bit to touch and it would cause a short.

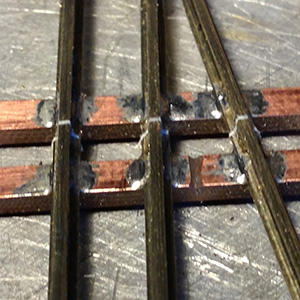

Follow along the pictures below to see what I do for my own turnouts on my own layout so this does not become a problem.

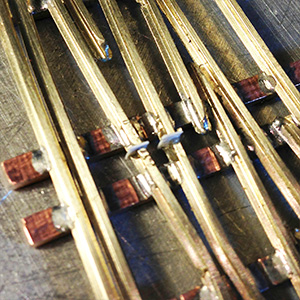

I place the styrene in the gap. It can be a tight fit but I slide it in so all the metal is protected one side from the other.

Underneath view. It is good to have it a little long on the bottom so you can add extra glue to really hold it in place.

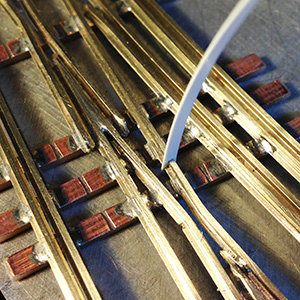

Using a toothpick I fill it up and all around with super glue. It’s OK to have extra glue because I cut and shape it to the contour of the rail after it is dry.

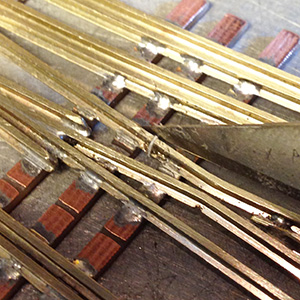

After the glue is dry (I wait until the next day or at least a couple of hours) I use an Exacto and/or files to shape the styrene to the same contour of the rail. Remember to leave the bottom long.

I use a bright boy to clean the glue off the top of the rail and it also makes the styrene flush with the top. Be careful when doing this near the end of the rail. Make sure that it is supported with a temporary tie so the short pieces don’t break off.

Hopefully this gives you a quick look at how I do this simple task that helps to eliminate potential problems down the road.